Table of Contents

The #1 Reason Why People Work with Aircrete

Hundreds of people with little to no building experience have joined a building workshop and gained the confidence they need to start their own project.

As someone who was once a beginner too, you're going to develop a skill to build, maybe even your own dome home. But right now, it's just about taking it one step at a time. You will find out for yourself that:

Aircrete is easy to work with.

DOWNLOADABLE & FREE E-BOOK

The Aircrete 101: Guidebook

Download our best DIY guide on:

Detailed instructions on: How to make Aircrete, pour Aircrete blocks and much more to get you dreaming big.

What is Aircrete

Domegaia coined the term Aircrete in 2014, it is also known as Aerated concrete, cellular concrete, foamed concrete, or lightweight concrete.

Aircrete is a lightweight, non-toxic masonry product that is made by infusing tiny air bubbles, in the form of foam, into a Portland cement slurry. The foam expands the volume of the cement many times, making it a low-cost building material and significantly increasing its r-value.

Simply put, Aircrete is a mixture of water, cement powder and a water-based foam.

Aircrete is fireproof, insect-proof, and unharmed by moisture - it will not rot or decay. It offers good thermal and acoustic insulation. Unlike concrete which is hard, heavy, cold, and challenging, Aircrete is easy to work with. It hardens overnight and can be cut, carved, drilled and shaped with wood-working tools. It accepts nails and screws and is easily repaired. It continues to set over time and makes excellent subfloors, building blocks, walls, domes, arches, and more. It can be molded or formed into practically any shape.

The Key is the Foam

Aircrete foam is produced by agitating a foaming agent with compressed air. A good quality degreasing dish detergent can be used as a foaming agent.

Not just any foam works for aircrete; it is a high-quality, specialized formula with a specific density.

For years, aircrete was only created commercially using heavy-duty equipment. However, when Domegaia founder, Hajjar Gibran, discovered the properties of aircrete, he invented special foam generators called the Little Dragon and the DragonXL to make it available to everyone.

Now, anyone wanting to build with aircrete can produce the foam required for Aircrete by combining high-pressure air and a soap solution.

Benefits of Aircrete

There are so many benefits to using Aircrete, but it depends on your application. While aircrete

Top Favorite Benefits are:

Low Cost

Customizable

Lightweight

Easy-to-find Ingredients

Temperature Control

To read a comprehensive article on 'Why Aircrete is Irresistible to DIYers'.

Ways to Use Aircrete

Aircrete is a DIY dream material. But what exactly can you do with Aircrete?

It is versatile as it takes the shape of anything you form it into. Even after aircrete becomes solid, it's easy to chisel, saw, cut holes into, craft into irregular shapes, and so much more.

To give you an idea of what you use Aircrete for, we've come up with a fun list here.

Aircrete Uses:

Dome Glamping Unit

Fencing

Spa Grotto

Sidewalk Pavers

Raised Garden Bed

Wall Panels

For a comprehensive list of over Over 75 Ways to Use Aircrete read more here.

Aircrete Tools and Equipment

To get a better idea of how everything works together. Let's start by taking a look at the entire Aircrete Building System. When everything is set up, this system produces as many batches of Aircrete as you need for your building project.

Bringing it all together...

1. THE AIR COMPRESSOR

Creates the air needed to make the bubble in the foam

2. FOAMING AGENT BUCKET

It contains foaming agent and water to supply the foam generator.

THESE BOTH CONNECT TO…

3. THE FOAM GENERATOR - Dragon XL

Allows the compressed air to mix with the foaming agent and pumps the foam into the mixer.

CONNECTS TO…

Injects the foam into the bottom of the cement mix and blends the foam and cement together.

BLENDS…

5. MIXING BUCKET

The mixer will now mix and inject foam into the mixing bucket that contains the 94 lb bag of cement and water.

POURS INTO…

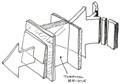

6. FORMS

The forms are used to make blocks and can be adjusted to produce 4”, 6” or 12” blocks.

How to get started making Aircrete

GETTING THE PERFECT WEIGHT OF FOAM

Aircrete is easy to make, but much like baking a cake, you have to get the recipe right. The quality and density of the foam are essential. Use an accurate kitchen scale to check the weight of your foam. When using dish detergent, It should be 90 - 100 grams/liter and 38-45 grams/liter when using Mearlcrete.

Dilute your foaming agent with clean water and mix thoroughly.

Seventh Generation Dish Detergent = 16 fl oz to 5 gallons of water

Mearlcrete Foaming Agent = 12 fl oz to 5 gallons of water.

MIXING STEP

In a 45-gallon plastic garbage can, mix one 94lb bag of cement with 6 gallons (US) water. Put all the water in your container first and add the cement while mixing to avoid clumping. When the cement and water are well mixed, turn on the DragonXL foam generator and use the foam injection mixer to blend the foam with the cement until you reach a few inches from the top.

POURING A FRESH BATCH OF AIRCRETE

Aircrete needs to be poured into a form and hardened overnight. Lay plastic down to keep the water from evaporating so it cures thoroughly. In dry climates, sprinkle it with water if needed.

Watch a Aircrete Brick Making...

How Strong is Aircrete?

A structure must withstand tension and compression forces - the two omnipresent gods pushing and pulling on all physical forms.

Aircrete has good compression strength for many applications but poor tensile strength. When fiber-reinforced cement is bonded to Aircrete’s surface, a composite material (Surface-bonded Aircrete) is formed that has both compressive and tensile strength. Surface-bonded Aircrete can be shaped into elegant architecture that will withstand the forces of nature and the test of time.

In the case of a dome structure, it is a self-supporting compression shell that requires little or no tensile reinforcement above its equator. The structural integrity of a Surface-bonded Aircrete dome is formed by the relationship between the composite material and the inherent rigidity produced by a dome's double curvature.

All other factors being equal, the more the curvature, the stronger the form. Conversely, flatter surfaces create weaker conditions.

When the forces acting upon a compression shell are understood and followed, we can build elegant structures of magnificent integrity. The art of designing equilibrium into a structure can create poetic shapes composed of harmonic geometry, expressing a graceful dance with the forces of nature.

A great analogy we like to use when it comes to building strength into Aircrete is to compare Aircrete to a surfboard.

The inside of the surfboard is light and breakable and the fiberglass layers on the surface of the foam are very bendy on their own. You get a composite material with new properties when combining the three layers. It becomes a durable, strong object with tensile strength and compression strength. The same goes for Aircrete. On its own, Aircrete is breakable; however, when you surround it with the inner and outer layers, you get a robust structure.

Making an Aircrete structure is much like a surfboard is made by bonding fiberglass fabric over a foam core, or drywall is made by bonding paper over gypsum. The layer of paper, fiberglass or strong fabric creates a tensile membrane on the surface that won't crack or break.

How Much Does Aircrete Weigh?

The weight of Aircrete is referred to as its density and depends on the recipe you are using. The goal is to have the Aircrete as light as possible while providing structural integrity. The lighter the Aircrete, the higher the R-Value and the lower the compression strength.

The Domegaia Recipe, ideal for building domes, arches, and other shapes, has a density of 22 lbs. per cubic foot.

The typical Aircrete Block is 3.75" - 4" thick and 12 in. x 12 in. and weighs only 6 lbs. 11 oz and has an overall density of 22 lbs per cubic foot.

Compare this to a typical cinder block that measures 8 in. x 8 in. x 16 in. and weighs 38 lbs. with a density of 63 lbs. per cubic foot.

Solid concrete has a density of 150 lbs per cubic foot compared to Aircrete at 22 lbs per cubic foot.

What is the R-Value of Aircrete?

R-value refers to the ability of a material to resist heat flow. The higher the R-value, the less energy is lost when heating and cooling a home. There have been many studies, and the R-Value of Aircrete turns out to be R-1.8 to R-2.2 per inch, depending on its overall density.

Even though the R-value of Aircrete is lower than foam board or other insulation products, because it serves multiple purposes, you can still achieve an excellent insulation level in an Aircrete wall.

Read our 'R-Value: Uncovering the Story' article for a deeper look into R-Value.

Aircrete and THERMAL MASS:

Aircrete has both R-value and thermal mass, a unique property for a building material. Consider the fact that most insulation products have no thermal mass but have a high R-value, and building materials such as concrete, adobe, and rammed earth have thermal mass but have a very low R-value.

Thermal mass is the ability of a material to absorb and store heat energy and then release it gradually. Insulating materials, on the other hand, prevent heat from passing through them.

Conclusion

In conclusion, Aircrete is a versatile, lightweight, cost-effective building material with numerous benefits and applications. As a mixture of water, cement powder, and a water-based foam, Aircrete is fireproof, insect-proof, and moisture-resistant. It provides excellent thermal and acoustic insulation while remaining easy to work with. Thanks to innovations in Aircrete equipment, anyone can now build with Aircrete and create unique and durable structures.

Despite its lower R-value than other insulation materials, Aircrete offers a unique R-value and thermal mass combination, making it a valuable material for various construction projects. From dome homes to fences and wall panels, Aircrete is an ideal material for DIY enthusiasts looking to create functional, aesthetically pleasing, and sustainable structures. With the right equipment, recipe, and technique, you can build your own Aircrete project and enjoy its numerous benefits.

Download our best DIY guide on:

Detailed instructions on: How to make Aircrete, pour Aircrete blocks and much more to get you dreaming big.